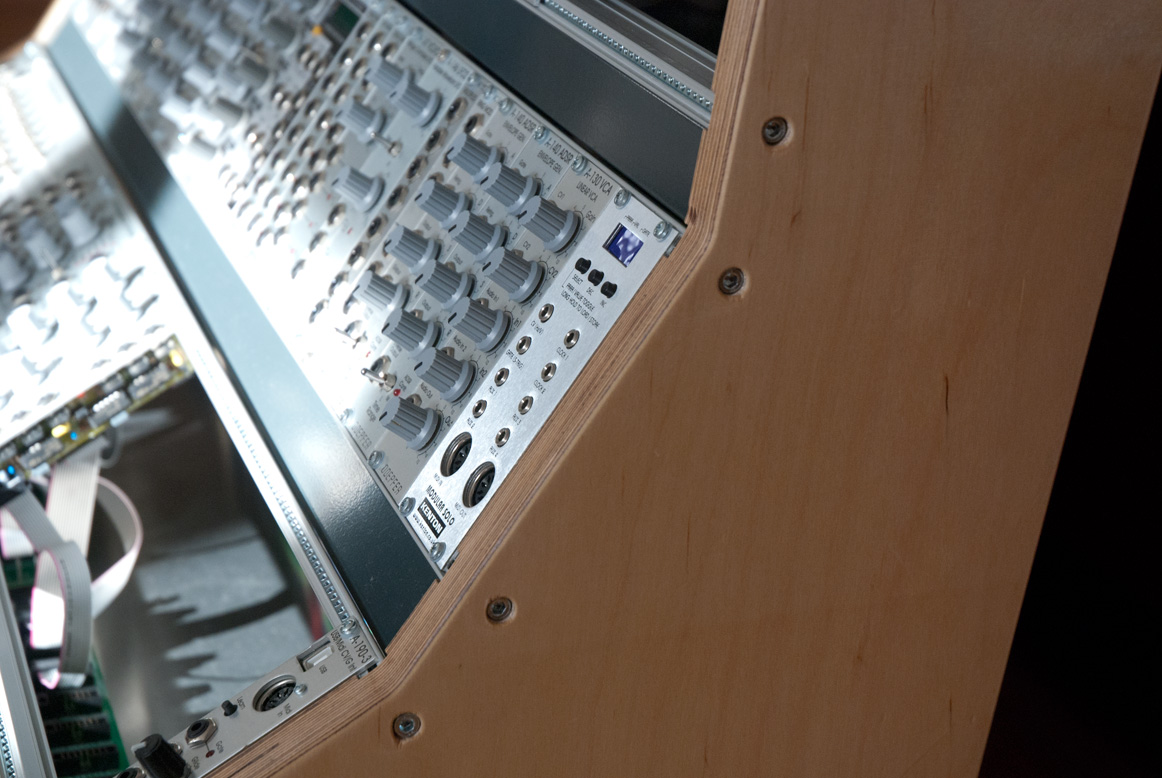

The final assembly and the installation of the modules.

The journey is over. 18 month of planning, development, side projects and work. I am really proud to present the result.

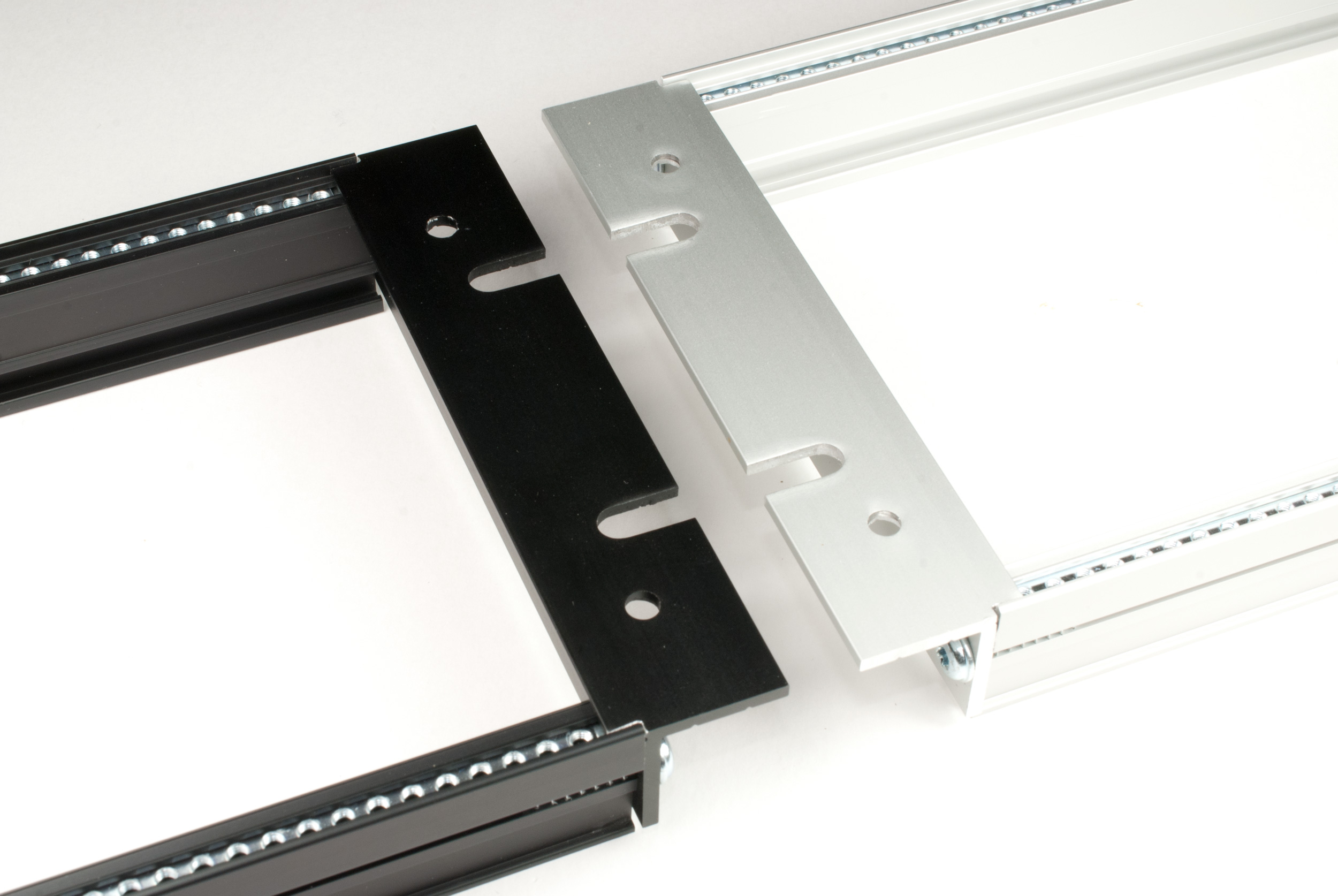

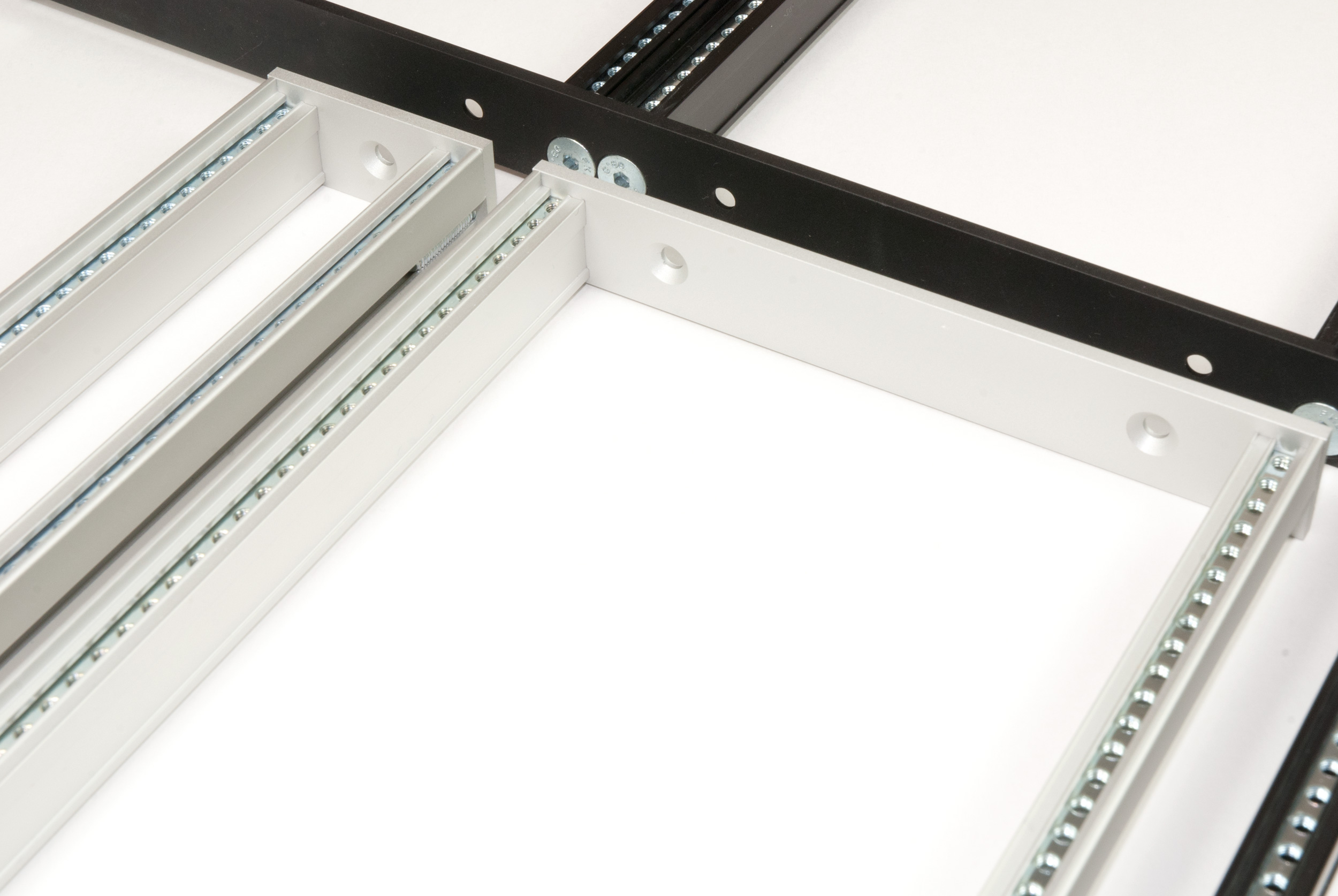

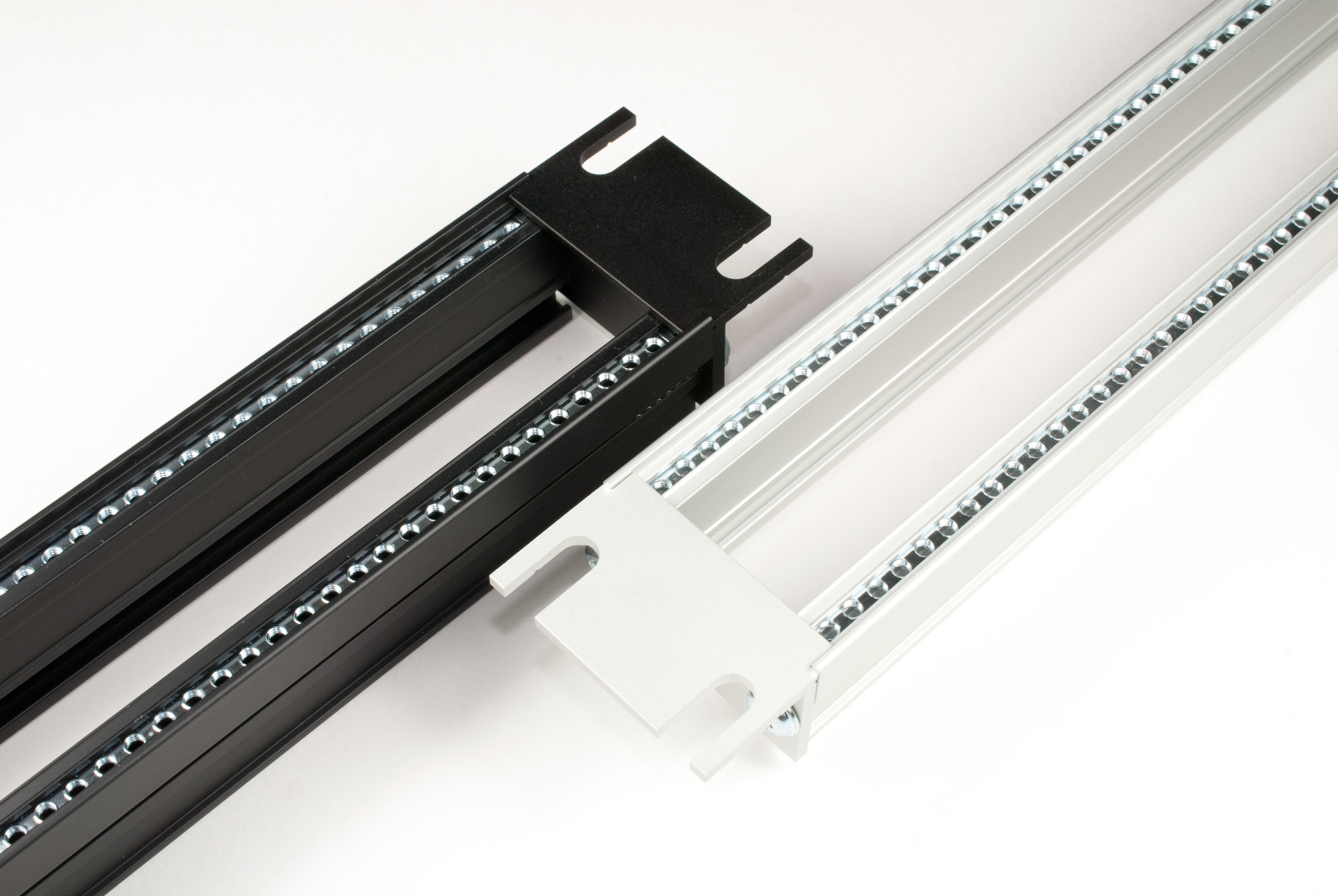

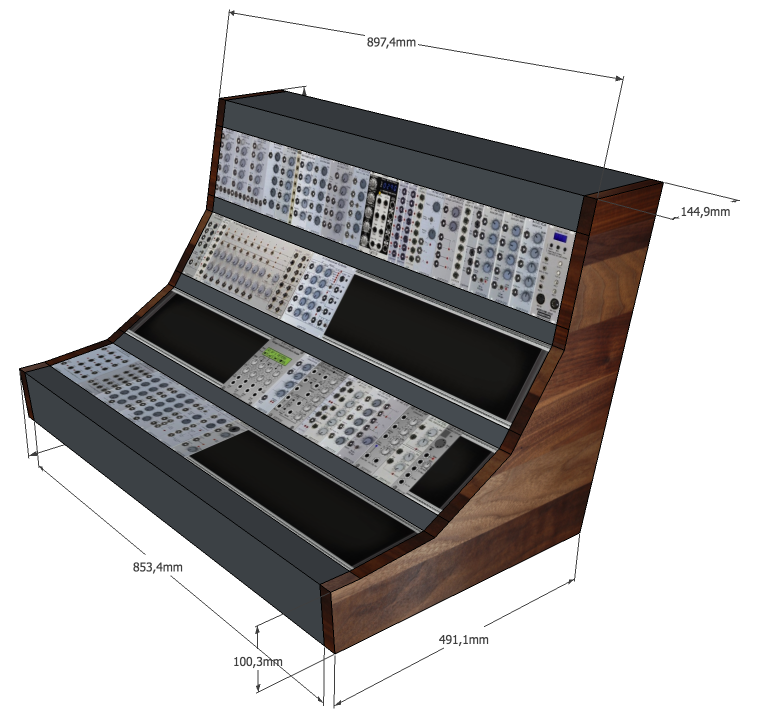

The idea was to have an ergonomically shaped Eurorack case. I also knew that the size should be around a Doepfer monster case with 12U. The main parameters where set: 12U, 168HP, 4 PSUs (+/- 12V, 4.8 A) , 8 busboards. I also knew the construction, wooden side panels (oil finish) clamping the aluminium panels (powder coated). The woodwork gave me the biggest headache as I don’t have a workshop where I could properly do the routing and sanding of the side panels. But I got it done altough it was a bit more effort with a flexible workshop.

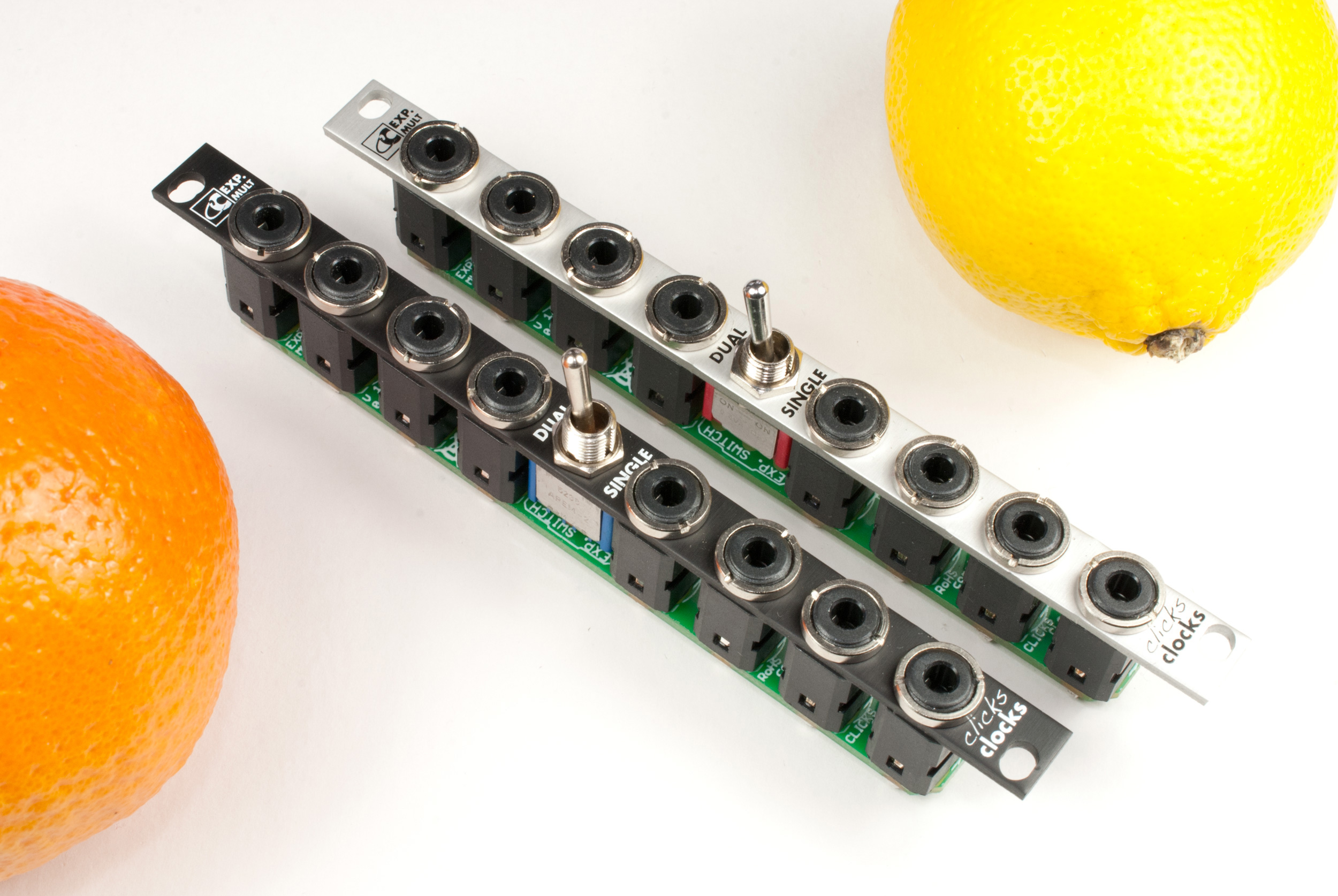

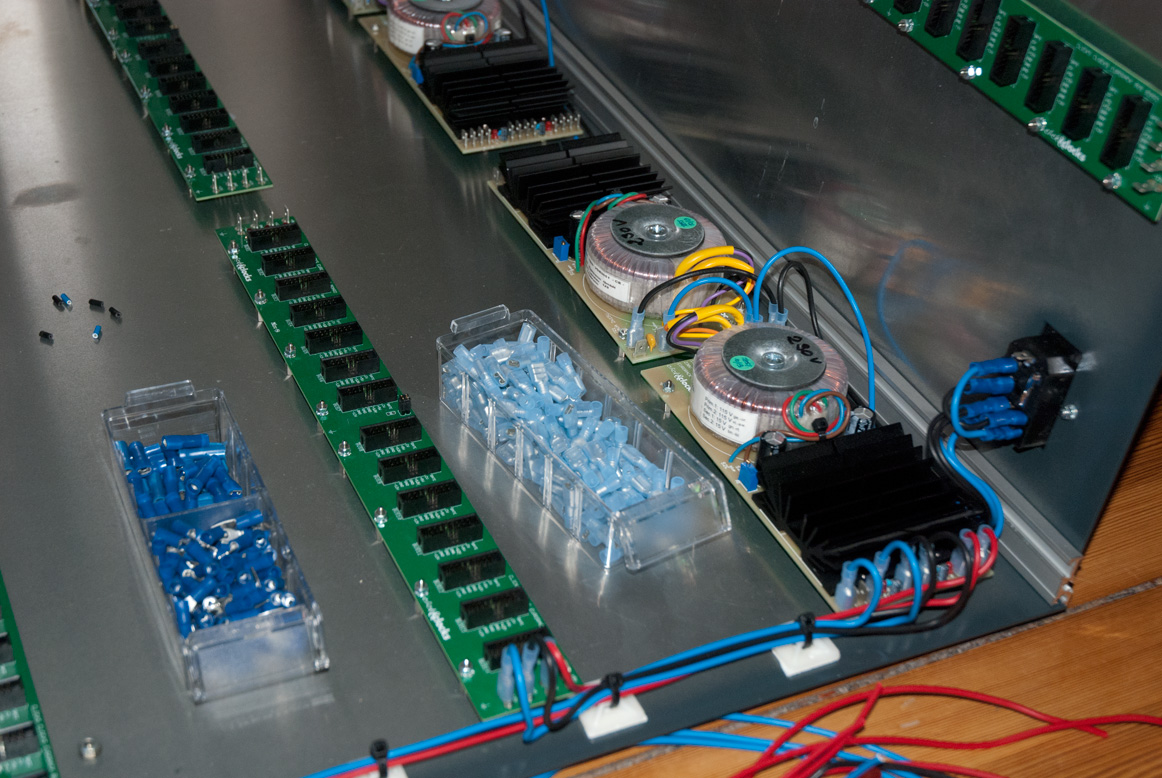

After the oil finish of the side panels and the mechanical assembly, I needed to do the complete wiring of the 4 PSUs, the 8 busboards and the mains inlet. The most amazing moment was the first powering of the complete unit without modules. It all worked as expected. Then it was pure fun to install all the modules in the new case. Now it is time to turn the knobs again.

One of the first sketches, done with Google SketchUp. It shows how exact the case was planned and then realised. Only the wood of side panels is a bit a compromise. I actually wanted to use walnut but then decided to go for multiplex or multilayer wood. I think I will replace the side panels at some point with solid walnut.

See yourself, here is the result:

If you want to read the full story, here are all the posts: